The Complex Process Visualization

Group. Details

The development of portable expert system for fault finding & maintenance of rolling mill

Project outline: In this project we investigate the possibilities of the SOM to perform condition monitoring of large DC motors for milling. Several variables of the motor were captured and, after feature extraction process (mainly consisting of obtaining the power content at certain fixed or variable frequencies), features were input to the SOM for process visualization tasks. We also applied RBF's (more precisely, kernel regression) in order to obtain a continuous SOM mapping, allowing to show small variations

Participant entities: University of Oviedo and Aceralia Steel Company

Project outline: This project aims to improve the quality of the tin plate coils obtained through a cold rolling milling process. A considerable high number of variables are available from the process, -such as tensions, mill speed, lamination forces, reduction ratios, composition of the lubrication oil, etc.-. The key idea is to use a SOM to model the relationships among all variables and to develop specific process visualization techniques to find out the main factors which have an influence on the coil quality. Some of the ideas we have in mind are the integration of available a priori knowledge such as fuzzy rules, known relationships among variables, etc.

Participant entities: University of Oviedo and Aceralia Steel

Company

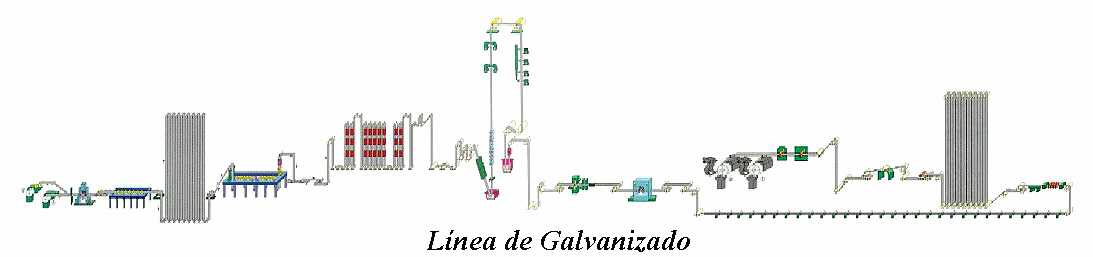

Modelo de presets para skin-pass

de la línea de galvanizado II basado en modelos híbridos

Project outline: In this project we use the SOM along with RBF's to perform nonlinear regression, to give an estimation of the coating thickness in a galvanising line given other process variables such as the line speed, temperatures, etc.

Participant entities: University of Oviedo and Aceralia Steel Company

Project outline: In this project we develop a capture and monitoring

system to collect and visualize up to 64 vibration variables in an electric

power generation plant for condition monitoring purposes. The system keeps

track of global energy levels and computes the power spectrum for all dynamic

variables, allowing to compare simultaneously spectrums of different variables

as well as to display the historical evolution of spectrums of specified

variables. This lets expert technicians to quickly detect faults into the

sensed devices.

Participant entities: University of Oviedo and Hidroeléctrica

electric company.